What could be a better time to talk about fashion? 2020, the year where the entire fashion industry is set to transform. From “what to consume” to “how to consume,” industry players are fixing the problem at every level.

In the fashion industry, Circularity is the new buzz word, trending even more than sustainability. Circularity is a new way of doing business, its a mindset. Fashion and apparel businesses across the globe are embracing Circularity in their business to attain sustainability. Though it’s not as easy as it may sound, apparel brands face many challenges when its to embrace Circularity.

Brands with skin-deep and short-term promises are no longer sufficient to put the sector back on track. Its high time for brands to make a fundamental and long-term commitment to redesign and rethink their textile value chain.

Here are three significant challenges of the circularity battlefield; fashion players are embracing.

Beyond Recycling

Recycling, the first idea to hits minds when it comes to Circularity. Many brands are focusing on recycling campaigns. While these efforts are worth celebrating, but that’s undoubtedly not enough.

Its time to rethink the entire process and redesign it better. The industry needs a shift from a linear model towards a circular model.

The most vital element for Circularity comes down to product end-of-life. And brands seek to optimize the Circularity of the raw materials in their products.

The industry needs to chase the restorative and regenerative supply chain that start at the very beginning of manufacturing apparel. For example, while adopting recycled material, its essential to know how sustainable the fiber-recycling process in and compare that to the energy level consumption for taking on the new raw material. The factors to ensure the sustainability of the recycling process are – water and energy consumption.

Get the environmental credentials of individuals suppliers to shift from polluting operators to Eco-friendlier ones. Another important benchmark is “Fibre Transparency,” which allows brands and consumers to examine the level of Circularity and sustainability in supply chains. As more and more brands are committing to Circularity, new sustainable standards can be set, boosting the economic, environmental, and societal outcomes.

Circular Economy Model

The circular economy model can ensure that “clothes never become trash.” Often fashion players find it challenging to shift their business model to a completely circular economy model from a linear economy model.

The circular economy works with technology, government agencies, research and multilateral organization, and education to identify and define circular jobs. It also determines the environment required to create and sustain them, as well as the technology that can facilitate advancement.

By embracing practices such as Repair, Rental, Resale, and Recapture, the fashion industry can start to unlock some of the $60 billion, that it currently misses out because of clothing are not used at the fullest before it is discarded, and then rarely recycled.

Brands need to look at new ways to meet consumers’ needs – Rental and Subscription – and also providing environmental benefits simultaneously.

According to Gwen Cunningham, the program lead of the Circle Textile Program at Circular Economy has defined the term” DISRUPT 7″ as the critical element of a Circular Economy.

– Design for the Future

– Incorporate Digital Technology

– Sustain & Preserve What’s Already There

– Rethink the Business Model

– Use Waste as a Resource

– Prioritize Regenerative Resources

– Team Up to Create Joint Value

A circular economy looks beyond current take-make-dispose business models, and redefine growth, focusing on a positive environment and societal benefits.

Advance Circularity

There are many advancements in the fashion industry to progress and encourage Circularity, yet there are many textile and apparel businesses that are missing on advance circularity.

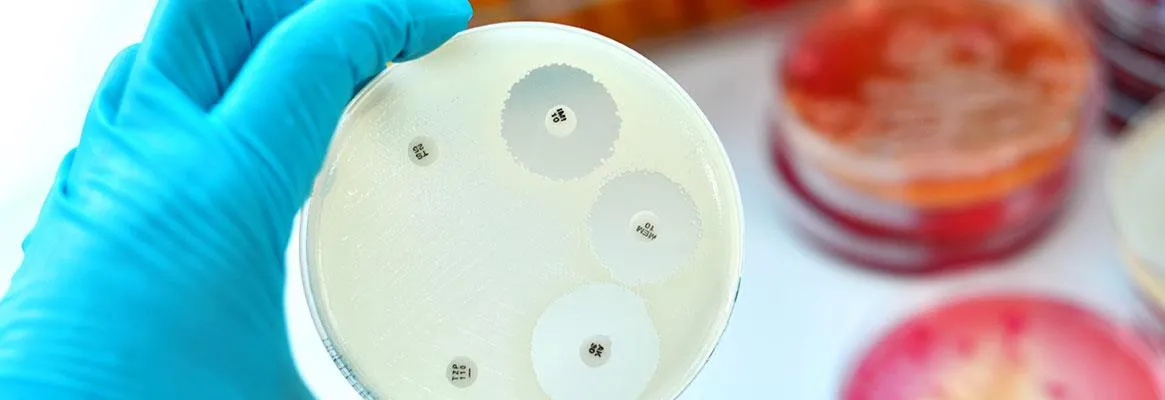

Most of the brands use recycled fabrics scraps as a part of advance circularity; the practice brings its host of challenges as recycling fabrics using blended fibers in extremely difficult.

The sorting of textile is one-of the time-consuming, inefficient, and often inaccurate efforts, to identify the fiber content. When clothes are recycled, they often turned into rags, insulation, or upholstery stuffing.

Cognizant of these challenges, many fashion brands are developing more sustainable fiber to replace the traditional blended fibers.

Avra– The fibers Avra are designed by Eastman Chemical Company to replace the activewear polyester. Also, the fiber can be recycled again into new fibers without compromising on quality.

Bio-Performance Fabric – PrimLoft has introduced 100 percent post-consumer recycled fibers that are designed for more extended uses and break down only when exposed to landfills or oceans. Also, the fibres can be recycled into new PrimaLoft fibres.

Apart from this, they are many apparel business using material science to create fabrics and products in eco-friendlier ways.

The Road Ahead

Despite all the circularity initiatives taken by the apparel industry across the world, according to Ellen MacArthur Foundation report, 15 percent of clothes are collected on recycling, and only 1 percent of clothing is recycled into new clothing. Seventy-three percent of the world’s total clothing eventually ends in landfills, as per the report of Global fashion Agenda and Boston Consulting Group.

The Journey towards Circularity has just begun; the fashion industry has to go miles to be sustainable and circular. All-size businesses are introducing Circularity through the entire value chain. From designing clothes to recycling textile waste, Circularity is everywhere. Brands are continuously chasing innovations to improve the quality of recycled fibre, but they still need to align their designs and manufacturing arms more tightly.

Along with industry players, government and policymakers also play a vital role in the Journey of Circularity. Policymakers are striving the innovative approaches of the textile and apparel industry to transiting to a circular economy.